CAPABILITIES

- Product Development

- Urethane Molding

- In-house flammability testing

- CNC Machining

- Extrusions

- 3D Printing

- Compression Molding

Thermal Forming

- Injection Molding

- Cut & Sew

POP Plating

- On-Wing Scanning

On-Wing Scanning

When you can’t source it, we can make it ! We have your solution to those obsolete and hard to source parts.Scanning capabilities to on-site, on-wing and manufacture parts within 6-8 weeks typically.

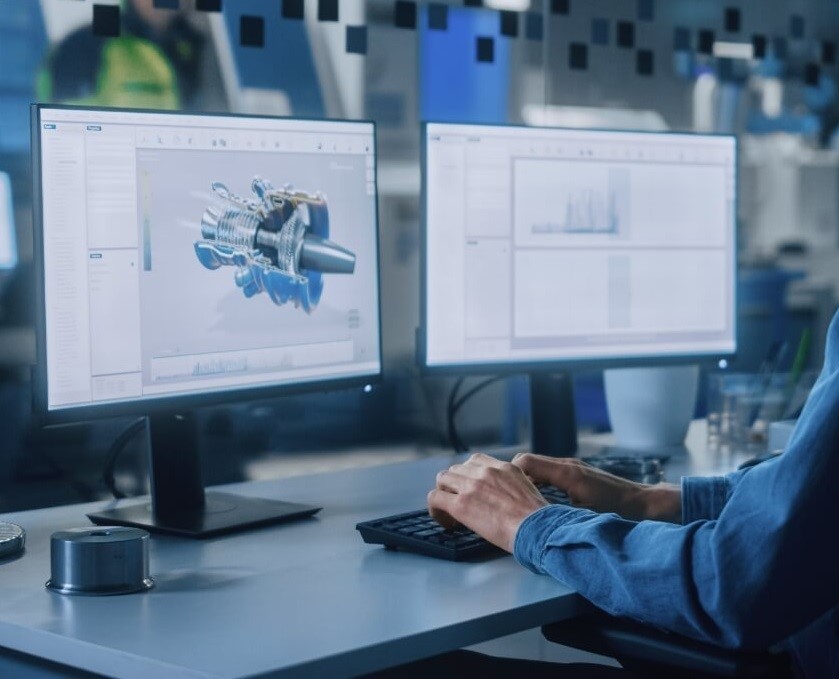

Engineering

Extensive engineering and programming expertise with Catia, Auto-Cad & Solidworks. Providing research and development in close collaboration with our customers including on-wing scanning, reverse engineering and rapid protoyping.

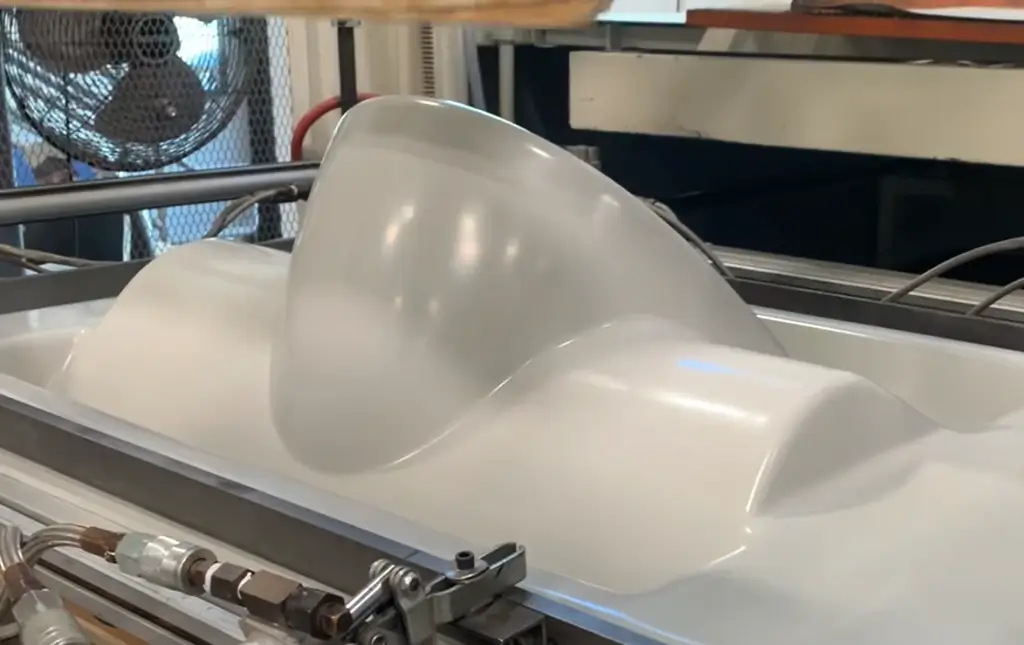

Plastic Molding

- Vacuum Forming

- Pressure Forming

- Compression Molding

- Injection Molding

Cut & Sew

Consew & Juki industrial sewing machines with highly skilled Artisans for all your cut & sew needs. From nose to tail, we manufacture quality aircraft interior upholstery and soft goods. From fabricated curtains, literature pockets, cargo nets, fire test safety blankets to seat covers fabricated from leather, e-leather, cloth, or fabric.

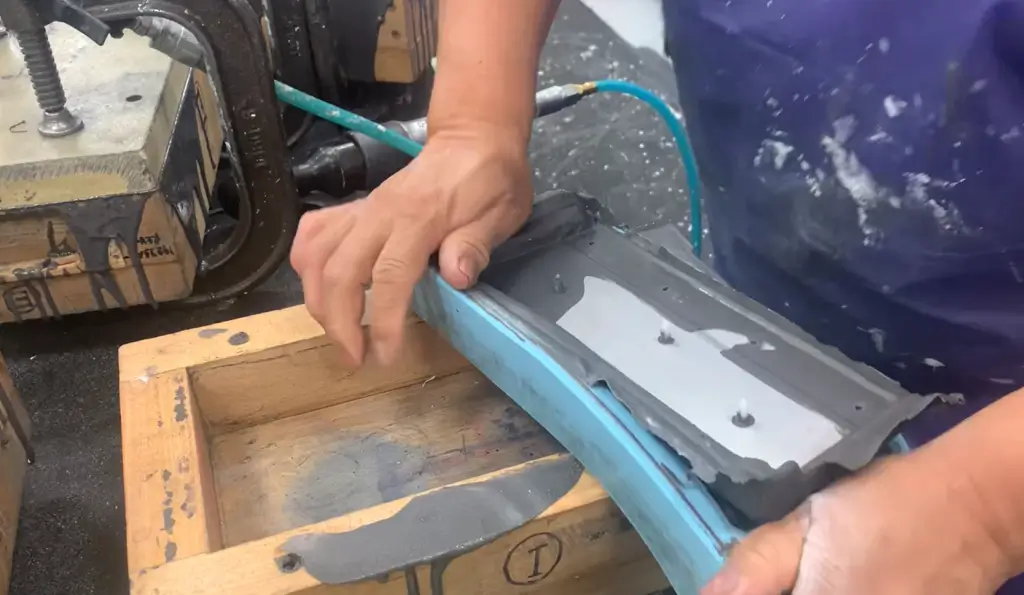

Urethane Molding

We are experts at cast molding with a wide range of proven polyurethane compounds and the ability to formulate compounds to meet specific needs of our customer projects.

CNC Department

Our CNC department excels in machining complex parts with tight tolerances and exceptional finishes. Utilizing advanced equipment like 5-axis CNC machines, 3-axis CNC machines, and 5-axis water jets, we deliver precision and quality that surpass industry standards, ensuring flawless completion of your most challenging projects.

Engineering

Utilizing a 3-axis programmable drag knife table, industrial sewing machines, and our highly skilled artisans, we cater to all your cut & sew needs. From nose to tail, we manufacture quality aircraft interior upholstery and soft goods, including fabricated curtains, literature pockets, cargo nets, fire test safety blankets, and seat covers made from leather, e-leather, cloth, or fabric.

Flammability Test

Our in-house testing ensures compliance with 14 CFR 25.853 (a) – Appendix F Part I, 14 CFR 25.853 (c), and 14 CFR 25.853 (d) fire safety standards. We guarantee that our products meet stringent flammability requirements, providing you with the highest level of safety and reliability.

Approved Aeronautics specializes in the production and certification of high-quality aircraft parts and components. With a commitment to precision engineering and stringent safety standards, we cater to the global aerospace industry’s demands for reliability and innovation. Our expertise ensures that every product meets rigorous regulatory requirements, ensuring safe and efficient flight operations worldwide.

Connect with us

- Hours are: 8:00 – 5:00 PST

- sales@approvedaeronautics.com

- 951-200-3730